Plastic Concepts

We are excited to be designing both carbon fibre and plastic/nylon composite products for the outdoor sector. With our own design team we can design and manufacture almost any solution you come up with. The only restriction is size, as the larger designs become prohibitive in terms of plastic injection moulding. And, we deliver plastic injection moulding outcomes at a 40% discount to the current market.

Design Process

The beauty of our process is that we design the concept for you at rates no one can match. We can provide basic prototype designs for as little as $250.

The Process

We offer a complete end-to-end service. With plastic injection moulding in Australia almost prohibitive due to cost, we design and do all prototypes here in Australia and then send your designs overseas for moulding.

Moulds are machined in steel and enable the manufacturer to inject the mould with molten plastic, cure and then provide the finished product.

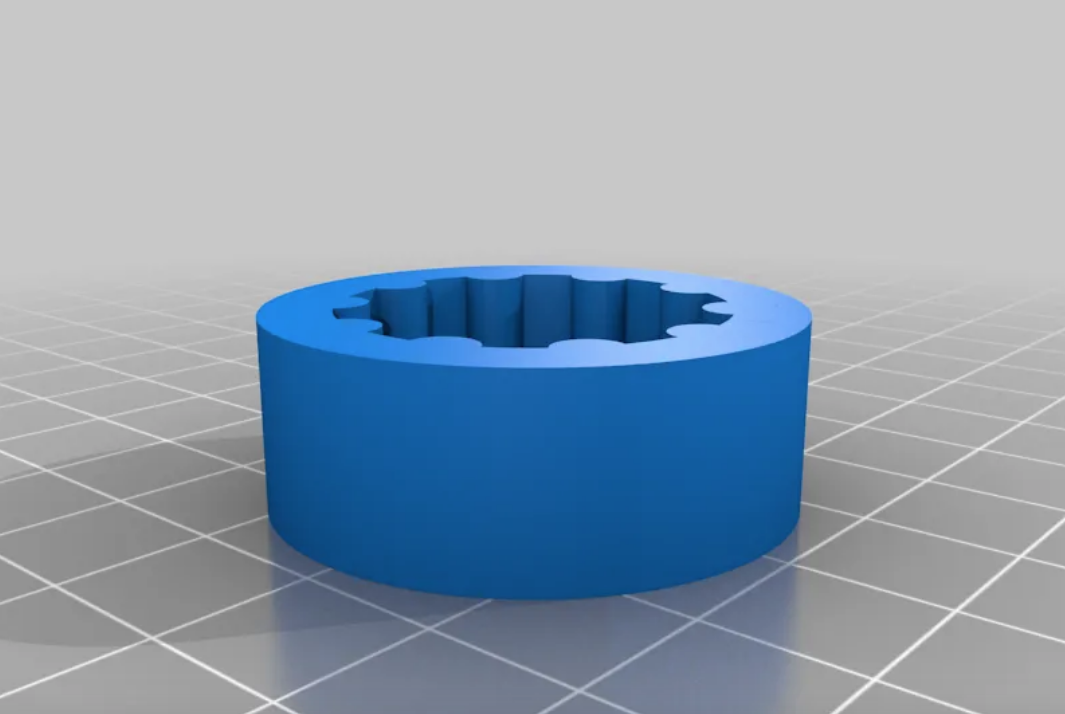

The value of our in-house plastic printing service is that we can develop prototypes cost effectively in plastic well before you have to invest. This means you have the time to get the drawings perfect prior to investing in the plastic moulding process.

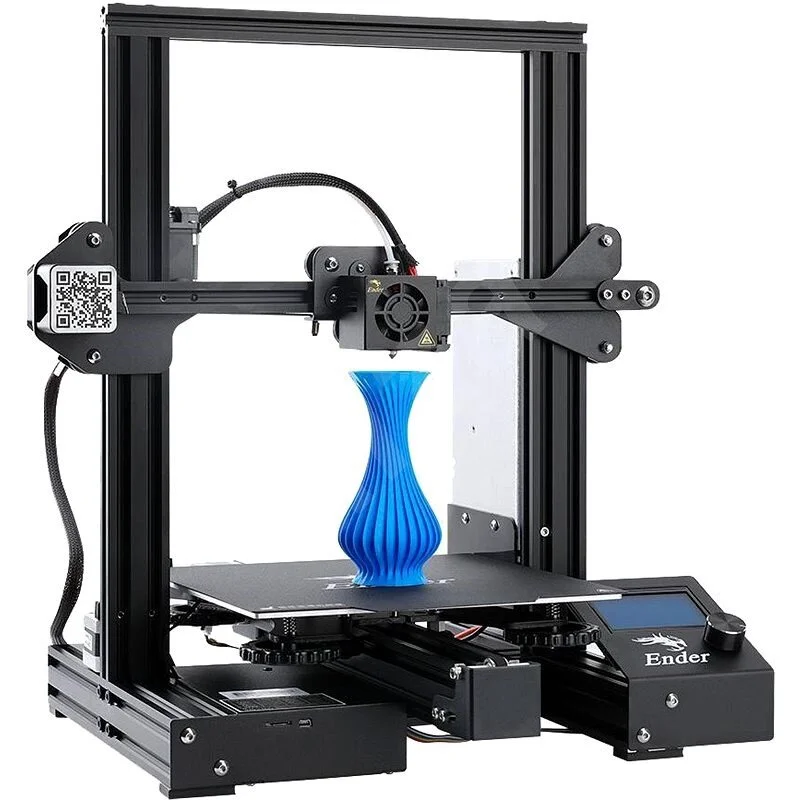

3D Printing

3D printing is exciting but at the same time complex. Everything has to be right to ensure prototypes are produced exactly as the client requests and that manufacturers can work with. That’s why we start here. Developing prototypes is extremely cost effective. It allows us and you, to analyse the design in real life and make any changes prior to moulds being paid for and made.